Automation

We have been automating our customers’ production for more than 30 years to allow them to concentrate on their know-how.

Icube, a multidisciplinary team of specialists at the service of your projects

Design of plans, programming of automatons, mechanics, pneumatics, electrical engineering, realization of electrical boxes, our multidisciplinary team accompanies you on the totality of an automation project. The automation of your production line requires many skills that we have at our disposal to ensure you the most coherent and efficient solution.

Icube supports your installations, from the oldest to the most modern

We are one of the pioneers of automation in Switzerland. Thanks to our 30 years of experience we know the old hardware and software systems. We have a stock of spare parts for older models of automatons. This makes us your ideal partner to maintain and modernise (retrofit) your installations, regardless of their age.

Icube assists you and answers you 7 days a week, 365 days a year

Our after-sales service intervenes 7 days a week, in the event of an incident, on site or remotely, to make your installation operational again as quickly as possible. The connected installations allow us to carry out an initial diagnosis and to carry out corrective actions, remotely and without moving, when possible.

Icube enhances your production data

We accompany you on the road to Industry 4.0 by using your data to optimize your production. We plan and carry out data collection and data backup in an automated, standardized way, even on heterogeneous machinery. We then ensure the integration of this data into your business applications, MES, ERP, business applications, and Icube applications such as Fabricube or the Mishell Suite.

Optimize the existing facility or start from a blank page

Upgrade your existing systems

Upgrading an installation (retrofit) extends the life of your machines. It is also an opportunity to optimize your production line. Icube helps you to define your needs, taking into account your production processes while complying with the safety requirements in accordance with Directive 2006/42/EC. We are familiar with the old hardware and software systems (allowing expertise on retrofits), including the stock of spare parts for old models of automatons. Our “installation” specialists produce and install hardware such as cabinets and electrical installations and then coordinate the installation with suppliers. This gives you a single point of contact that makes your renovation easier.

Automate your new installation

The automation of your production line requires many skills: design of plans, programming of PLCs, mechanics, pneumatics, electrical engineering, as well as the realization of electrical boxes. Our multidisciplinary team will assist you in all these aspects, to ensure you the most coherent and efficient solution. We work as closely as possible with manufacturers and installers of production lines to carry out your automation projects from their design to their commissioning. We respect the industry standards related to machine states: PackML, ISA 88 and ISA 95, GAMP5… Our products are also compatible with the CFR21 part 11 standard.

The Icube experience in a few figures

More than 1000

Implemented projects

30

years experience

More than 250

satisfied customers

The automaton manufacturers we work with

Depending on the existing situation and customer requirements, we are happy to work with manufacturers such as Rockwell, Siemens, Schneider, Beckhof, B&R… The robustness of these solutions guarantees a long-term partnership with our customers. Our experience in the fields of food, chemicals and the environment has been accompanied by a strong partnership with the American manufacturer Rockwell. Our Rockwell certifications include control, process and safety (unique in Switzerland).

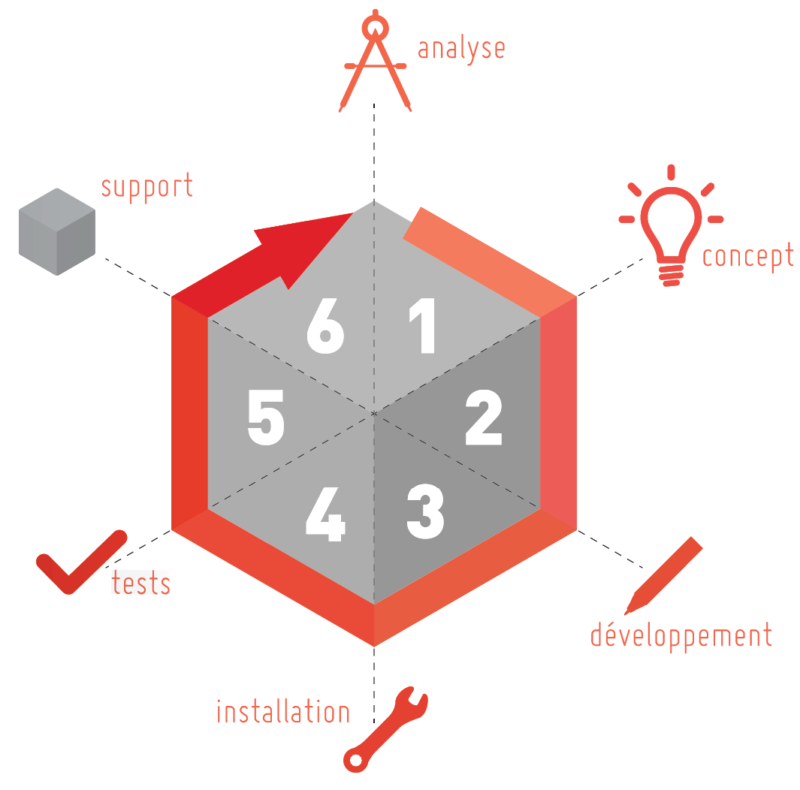

The intervention phases

An automation project follows in most cases the form shown opposite. We accompany you through all these phases, from the first visit of the installation to the support of the implemented solution.

1) Analysis: Study of your installations, risk analysis according to ISO 12100 and elaboration of specifications.

2) Concept: establishment of technical specifications in partnership with the client.

3) Development: PLC programming, supervision, Web applications and “reactive” PCs, assembly of electrical boxes / cabinets, integration into the information system.

4) Installation: Supplier coordination, automation assembly, installation of software platforms and measuring devices.

5) Tests: unit tests, integration tests, functional tests, compliance, commissioning and production start-up.

6) Support: We provide initial support during commissioning and user training, and then provide a 7/7 and 365 days a year after-sales service.

Applications and services dedicated to your production

With EVA, monitor and analyze your production

Opt for an after-sales service close to you

Improve the safety of your employees