Your digitalized production

Optimize your installations

With our remote maintenance solutions, specialists can, at your request, connect to your plant to provide advice, adjust settings, or diagnose possible malfunctions without having to travel to your site.

Our after-sales service intervenes quickly 7 days a week.

Guarantee the safety of employees

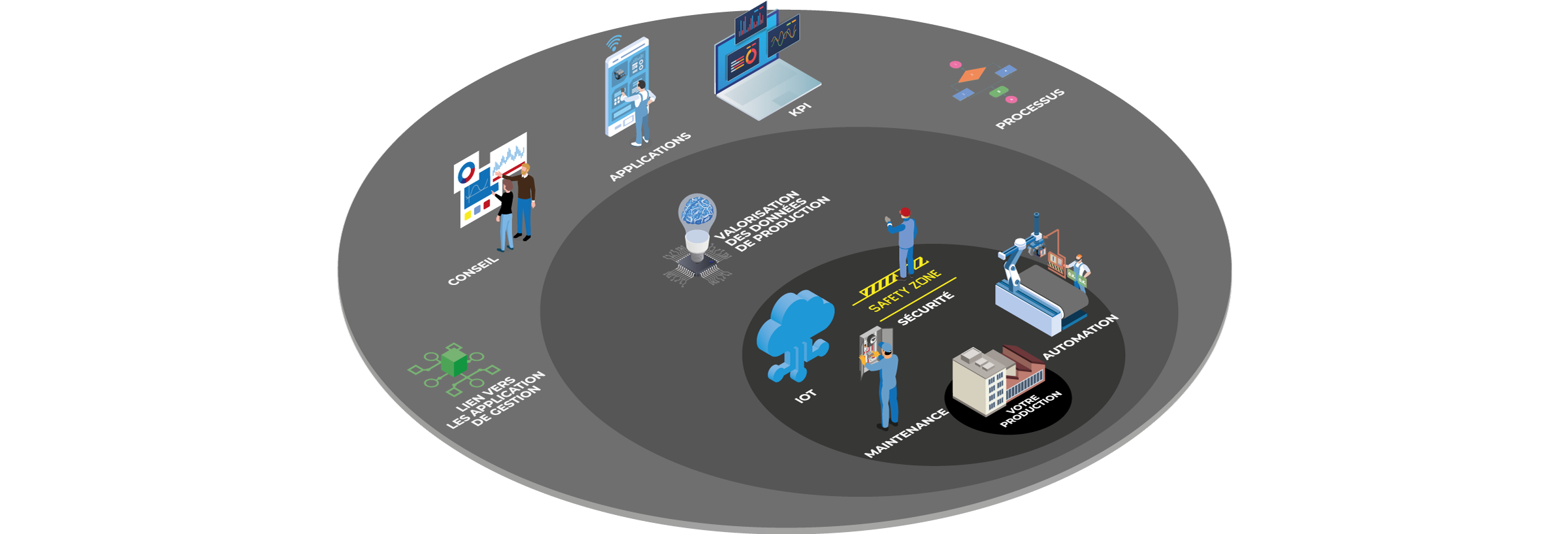

Get complete control of your production digitization project

– The control of the production lines

– Expertise in information systems

– Change management

Icube will help you define a product that combines these three concepts and that meets your company’s vision.

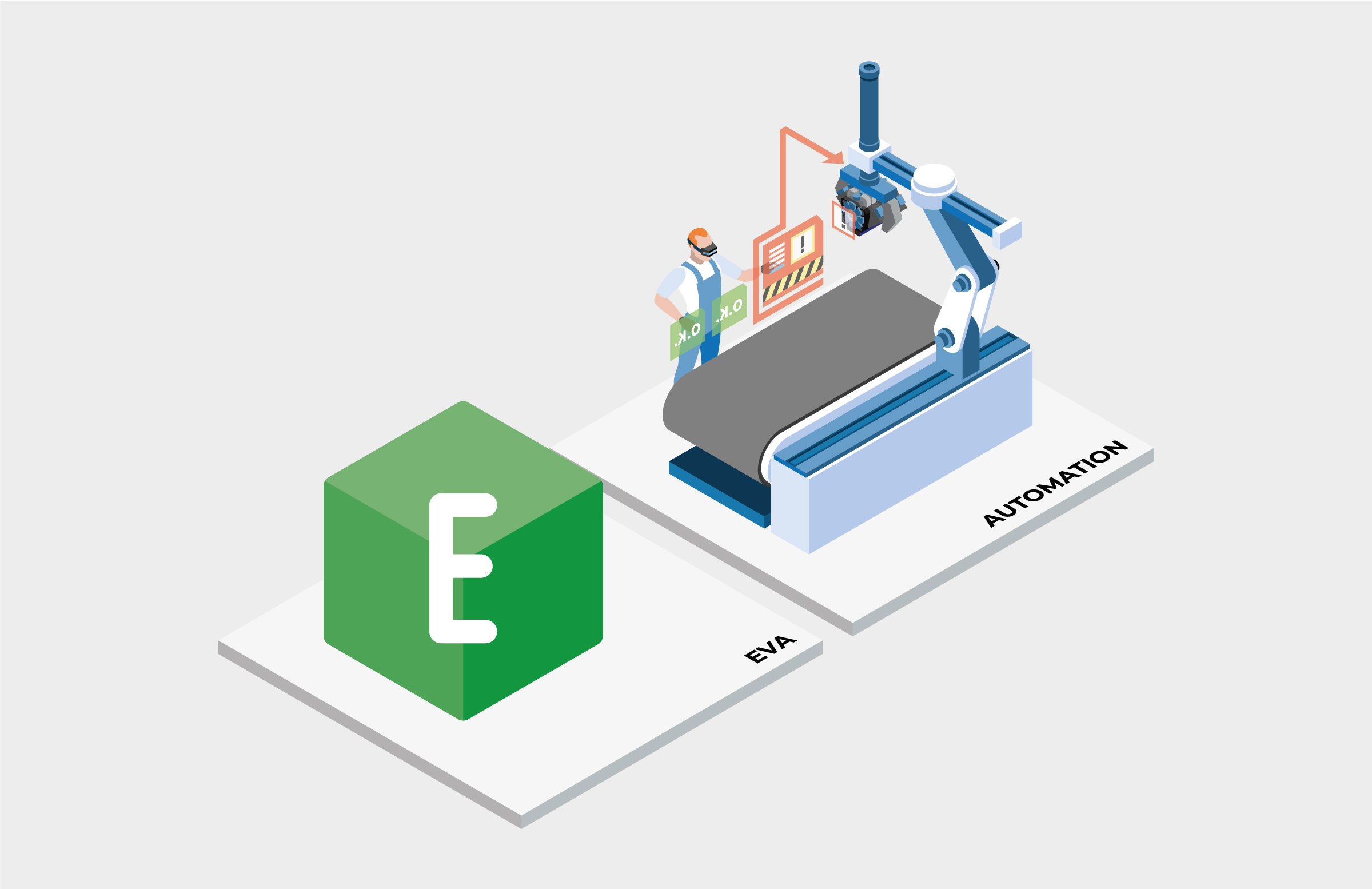

Ensure the regularity of the quality of your production

Data traceability is guaranteed without having to store paper. Find your measurements in one click and easily browse your production history.

Increase the availability of your installation

Improve your processes

Softwares dedicated to your production

With EVA, monitor and analyze your production

Plan your care and maintenance

Testimonials

Icube and the production digitalization

Solutions for all

We currently accompany both self-employed craftsmen and multinationals. Indeed, our ability to adapt and customize, as well as the versatility of our solutions allow us to respond to problems from the most elementary to the most complex. Our proximity to our clients and our ability to provide advices make our difference.

From the workshop to the manager’s office

Your production data must first be captured from the machine, then standardized, aggregated, analyzed and finally returned as a production indicator, or linked to other data in your information system. Icube can help you through all these stages: from sensor installation, integration of programmable logic controllers, data evaluation and output, to integration with external systems. You thus benefit from a single point of contact for the entire chain, from the workshop to the manager’s office.

A common road to industry 4.0

Moving from a completely manual job to a smart factory is not done in a day. You have probably already started this route and are enjoying the benefits of automation or digitalisation. At any time, we can join you on this journey to help you better define your objectives, implement the best technologies, and finally ensure optimized and secure production.