Customer benefits of the Icube solution:

Converting a complex Siemens program to Rockwell

Specific interfacing with a Pharma MES

Automation of a high-stress batching process

Customer testimonial

Visval’s business

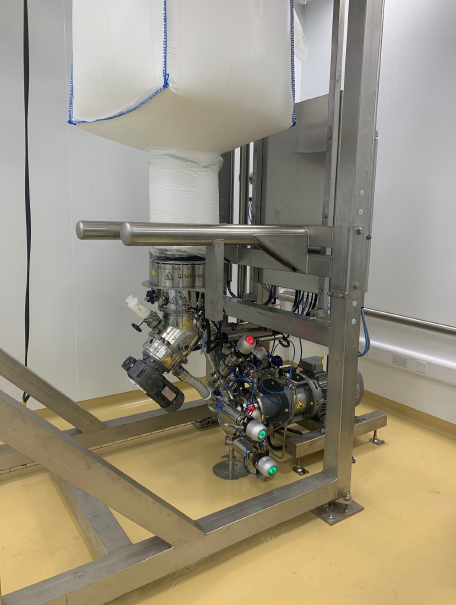

Visval is a Swiss company based in Düdingen that offers automated powder dosing solutions via its SoliValve® product, mainly for the pharmaceutical, chemical and food industries.

Do you have a similar need?

Icube carries out projects related to the automation of pharmaceutical and agri-food processes in a wide variety of customer environments.

Visval’s requirements

Visval products were primarily designed around a Siemens automation architecture. As some of Visval’s customers work in technical environments linked to the supplier Rockwell, Visval had to adapt to this technology to be able to offer its products to a wider customer base.

The scope to be supported concerned a Siemens automation program.

The scope to be supported involved a very dense and complex Siemens program and supervision, both of which needed to be optimized and then converted to Rockwell architecture.

With this new architecture and an initial customer installation to implement, Visval was also looking for an implementation partner who could travel internationally to assist with on-site commissioning.

Icube, backed by a long-standing partnership with Rockwell and also proficient in Siemens technologies, was chosen by Visval to support them throughout its projects.

The solution implemented by Icube

To meet this challenge, Icube first had to analyze the initial program with Visval’s automation team, select the functions to be converted, optimize the existing and finally rewrite the program in the Rockwell environment. An additional layer of safety (emergency stop management) was added to the program.

After a few validation sessions with Visval, the new program driving the various peripherals was ready to be implemented at a first customer.

Icube then went to the Pharma customer’s site to accompany Visval during commissioning.

In this context, the powder dispenser was controlled by a Pharma MES (Manufacturing Execution System), so Icube carried out the integration between the dispenser and the customer’s MES for complete integration of the product into the production chain.

Do you have a similar need?

We carry out automation and production optimization projects all over Switzerland.

EVA: The complete equipment monitoring application:

With EVA, monitor and analyze your production