Case Study – Gasser Ceramic

Sensors rub shoulders with people in the service of century-old Swiss know-how

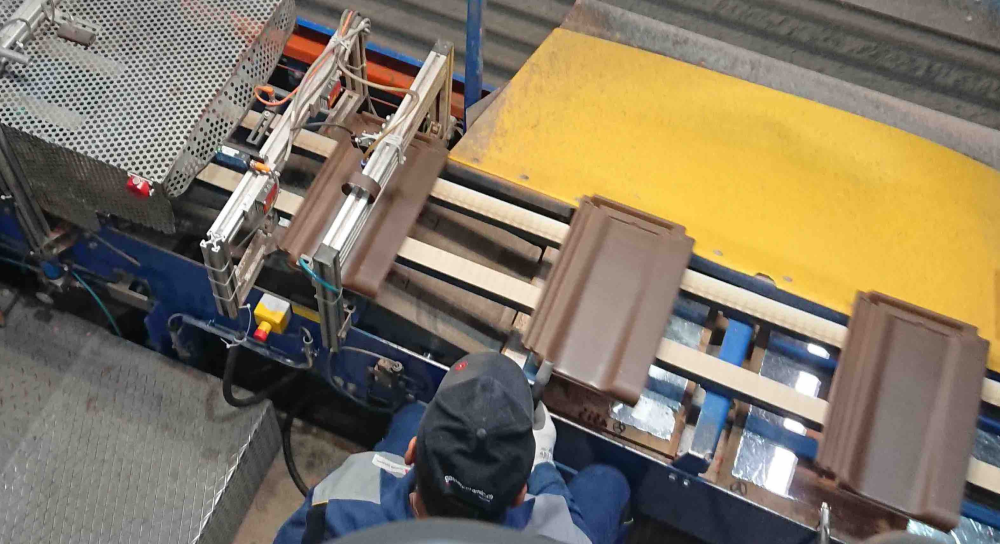

Laser sensors measure every tile on the production line. Pieces that don’t match the reference profiles are automatically sprayed with a jet of water. Elles sont ensuite mises de côté manuellement par les experts de qualité. In this way, Gasser Ceramic know-how is optimized!

- Measuring tile flatness

- Modularity and agility

- Simplifying an existing concept

- Project development in simulation

- Statistics

- Bringing sensors and people together

Measuring tile flatness

Lasersensoren kontrollieren die Ebenheit der Dachziegel. Jedes Stück wird vermessen und diejenigen, die nicht dem festgelegten Referenzprofil entsprechen, werden automatisch mit einem Wasserstrahl besprüht. Diese Markierung ermöglicht es den Mitarbeitern der manuellen Qualitätskontrolle, unvollkommene Dachziegel aus der Produktionslinie zu nehmen.

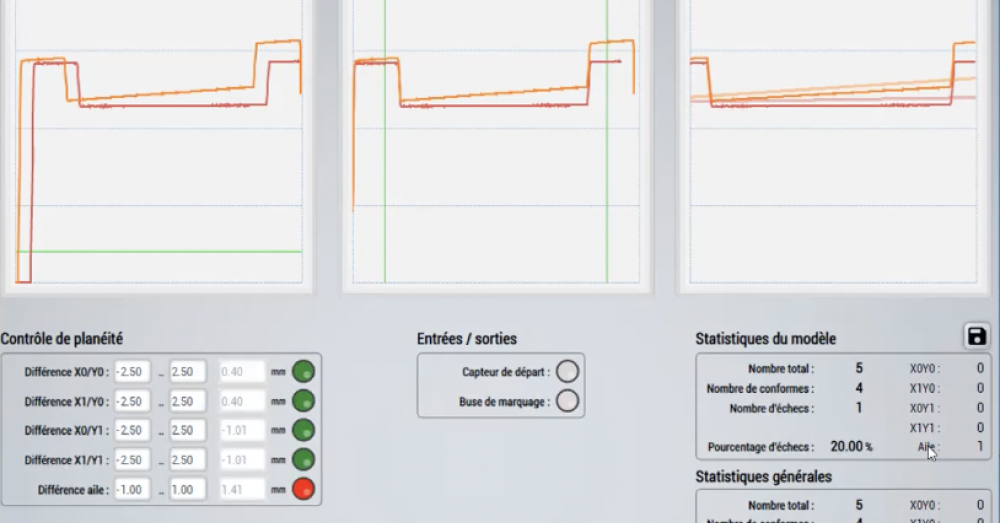

Modularity and agility

- Gasser Ceramic users can select the different profiles stored according to the tile models to be produced. They can easily modify all profile comparison parameters.

- The system is multilingual.

Simplification of an existing concept

Icube was able to simplify and reactivate an existing system that was no longer working and was very complicated.

Project development in simulation

The development of the solution was based on simulation, which led to a number of advantages:

- ignore delivery times for production materials

- take advantage of the simulator’s safety aspect

- Gasser Ceramic employees were able to test the concept very quickly, and discussions with Icube were rich and numerous.

Statistics

The system delivers daily statistics. They can be included in general production statistics, or taken individually according to selected criteria.

Bringing sensors and humans together

Gasser Ceramic benefits from a hundred years of know-how, and the company still preserves the manual gestures that are so precious to it. The human touch rubs shoulders with laser sensors on the production line, ensuring unrivalled Swiss manufacturing quality.

Gasser Ceramic benefits from a century’s worth of expertise, and the company still retains invaluable manual skills.

“

We commissioned ICUBE to replace our tile flatness control system. The idea was to keep part of our system in place, and redo the management of data acquisition and processing. Working with ICUBE was simple and effective. Our needs were quickly understood, and commissioning went very smoothly!

Cédric Vienne

Morandi Electrical Maintenance Manager

Gasser Ceramic

Like Gasser Ceramic, opt for a ICUBE solution tailored to your production line

Schedule an appointment with our teams today to discover a customized solution

Discover our other case studies

© Gasser Ceramic