Fabricube Industry

Assurez la qualité et la traçabilité de votre production

You keep control over all stored data.

They are cross-referenced in reports to allow you to immediately identify areas for improvement or alerts.

You thus easily have all the data you need to report to the control authorities (your management, customs, project portfolio, obtain a TRS, etc.). You ensure the traceability of your products and your equipments.

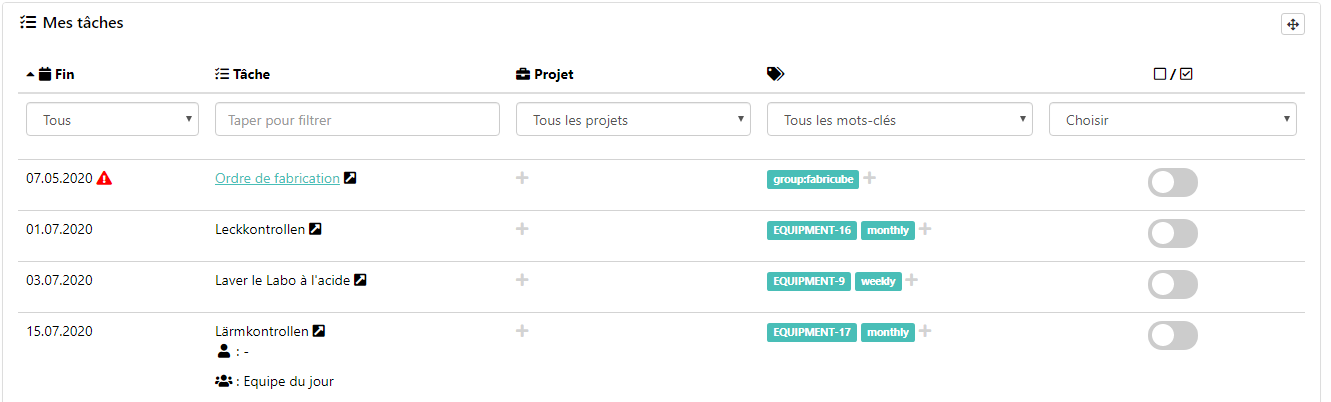

Planifiez votre production et automatisez vos maintenances, nettoyages et entretiens en quelques clics

You will also be able to plan your future production several months in advance, all of which is integrated with your production sheets and your stock.

Planifiez vos tâches et celles de vos collaborateurs

It will even be possible to target several tasks at once to save time. Finally, thanks to our reports, you will keep a global vision of what is done or remains to be done during the day, the week, the month…

Organisez au mieux votre usine grâce à nos modules de gestions

It is available on computer, smartphone and tablet for a complete user experience adapted to your business.

For more than 30 years and after more than 1,000 projects completed, we have been helping our customers to optimize their production. We master the complete chain, from production automation to the director’s decision to bring you transversal and tailor-made solutions.

Our solutions integrate with each other to bring you the greatest coherence and allow you to focus your collaboration with a single partner, available 7/7d, 365d per year.

Depuis plus de 30 ans et après plus de 1000 projets réalisés, nous accompagnons nos clients dans l’optimisation de leur production. Nous maîtrisons la chaîne complète, depuis l’automatisation de la production jusqu’à la décision du directeur pour vous apporter des solutions transverses et sur mesure.

Nos solutions s’intègrent entre elles pour vous apporter la plus grande cohérence et vous permettre de concentrer votre collaboration avec un seul partenaire, disponible 7/7j, 365j par an.

Fabricube features:

Production monitoring:

– Creation of personalized production sheets

– Automatic or manual entry of production data in the manufacturing sheet as well as all the information necessary for traceability.

– 100% developed in Switzerland. Hosting on Icube or client servers, with the possibility of hosting in Switzerland.

Planning and Scheduling:

– Production planning

– Planning of maintenance, cleaning and servicing

– Task planning, execution and control

Production management:

– Stock management (stocks automatically consumed according to your production)

– Customer database management

– Registration of cleaning product certifications

– Follow-up of the control of measuring devices

– Management of non-conformities (quality)

– Registration of working hours and vacation planning, request for leave.

– Follow-up of safety training at work (equipment audit + electronic signature of each employee)